Energy Efficiency Controlling in the Automotive Industry

Currently, sustainable energy consumption is one of the most intensely discussed topics related to technological development. In the future, with increasing energy costs and ecologically motivated regulation, it will more than ever be a critical factor for successful new technologies and products. Accordingly, the perception of energy efficiency in industrial production is changing into that of a cost-relevant resource and can clearly be regarded as a potential competitive advantage in the manufacturing process.

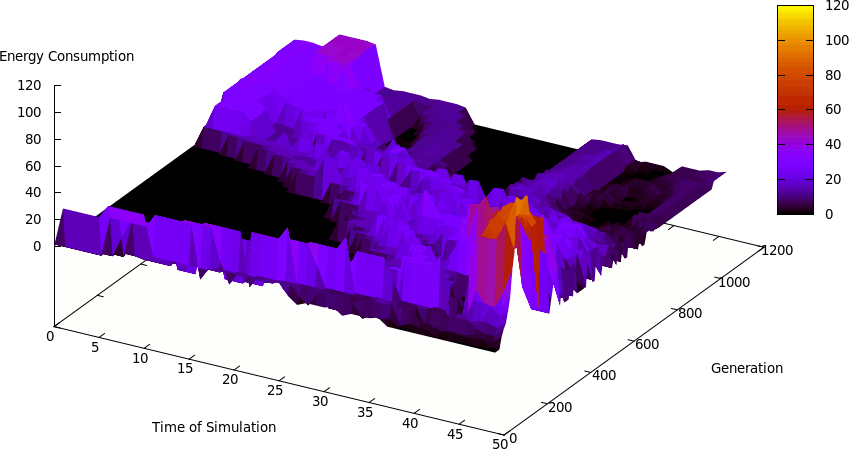

The EneffCo project is funded by the Federal Ministry of Economics and Technology. It pursues the goal to develop and implement a novel hard- and software concept that facilitates the reduction of energy consumption and energy costs in the automotive industry. DAI-Laboratory’s partial project specifically aims at the realization of a modular software system to simulate operational modes of plant sections with relevant energy consumption. The software serves as a tool for decision makers in manufacturing, to whom it offers the identification and evaluation of strategies and tactics for establishing cost and energy efficient production schedules. These schedules may be regarded as suggestions for production plan improvement, which are identified, evaluated and depicted, before these plans are considered to be put into action. Efficient production planning is determined on the basis of energy and production specific input data, such as production rates or energy costs that can be specified by the production manager. Specific input data could for example be to produce a certain number of items within a specified time period without exceeding a maximum aggregate electricity grid load. Energy parameters can e.g. be the overall amount of energy, a maximum load level or load shape transformations.

For the realization of the simulator, software paradigms from the artificial intelligence domain are used as well as rule based optimization systems. Domain modelling is done in an ontology-based approach to establish a generic data model as a basis for adaptation and interoperability beyond the scope of this specific project. Furthermore, the simulator is implemented with a modular software concept that facilitates the easy development and integration of new manufacturing and energy production resources.